This rehabilitation method is intended to prevent leakage from medium-B-pressure and low-pressure pipelines at joints, cracks or fractures, as well as leakage caused by earthquakes.

The rehabilitation work only requires excavation at both ends of the target section and cutting the exposed gas pipes. The required period and cost are shorter and lower than incurred by gas pipe replacement.

- (1) Excavation/Pipeline Cutting:

- Excavate at both ends of the target section and cut the pipeline.

- (2) Cleaning:

- Attach a cleaning tool to the winch and pull the tool to clean the inner surfaces of the pipeline.

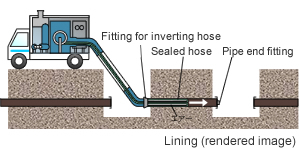

- (3) Lining:

- Provide a lining by inverting a sealed hose in the pipe.

- (1) Rehabilitation of a long span (up to 200 m) in a single session

- (2) Rehabilitation of complex piping comprising 90o elbows

- (3) Excavation of only two locations per rehabilitation span

(Reduction of the amount of excavated soil)

| Pressure | Medium B/Low pressure |

|---|---|

| Pipe size | 100A to 400A (excluding 350A) |

| Pipe type | Cast-iron/welded steel |

| Piping | Up to four 90o elbows (not suitable for pipeline comprising a change in diameter or branching) |

| Length | Up to 200m |