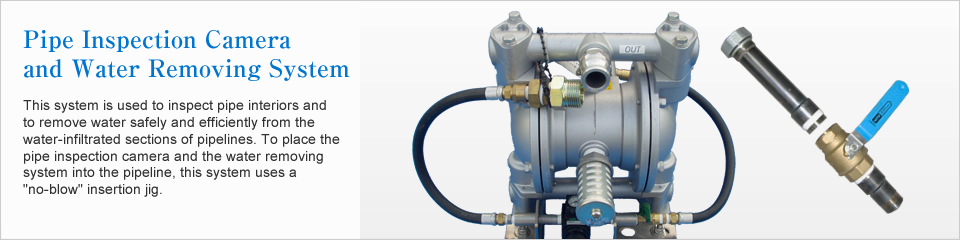

This system is designed to inspect pipe interiors and to remove water safely and efficiently from the water-infiltrated sections of pipelines. To place the pipe inspection camera and the water removing system into the pipeline, this system uses a newly developed "no-blow" insertion jig.

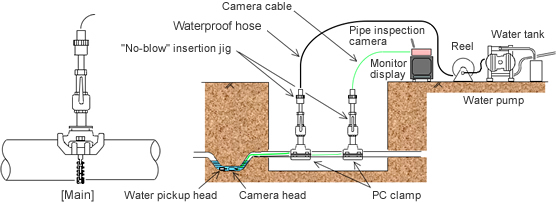

The "no-blow" insertion jig is attached to an existing branch clamp (or bypass saddle in the case of a PE pipe) on a low-pressure live pipe or to a bored live main. The pipe inspection camera examines problem areas. At the same time, a pneumatically driven diaphragm pump is used to remove water from the live pipe.

This system, incorporating a REX special-order pipe inspection camera, "no-blow" insertion jig and branch/main water removing system, is used to repair pipes to fix water infiltration.

| Pressure | Low |

|---|---|

| Pipe size | 50A - 150A |

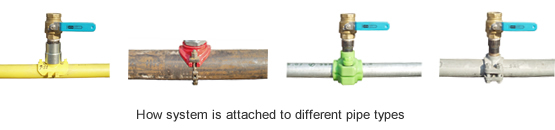

| Pipe type | Steel, cast iron and PE |

| Pipe inspection camera | Insertion length: up to 30 m on one side |

|---|---|

| Water removing system | Max. capacity: 9 L/min |

| Range: up to 30 m on one side | |

| Passage through piping with bends | Not possible to insert into conventional branches and PE pipes with an elbow. Can pass through a main with up to four 45o bends. |

- (1) By fitting an adapter, the insertion jig can be attached to all types and sizes of pipe without using any special device or material.

- (2) The "no-blow" insertion jig requires no special clamp, since it is attached to a branch by an existing PC clamp (white clamp for 65 mm pipes) and, in the case of a cast-iron pipe, to a directly bored hole.

- (3) The system enables the operator to remove water with reliability while monitoring the water level with the camera.