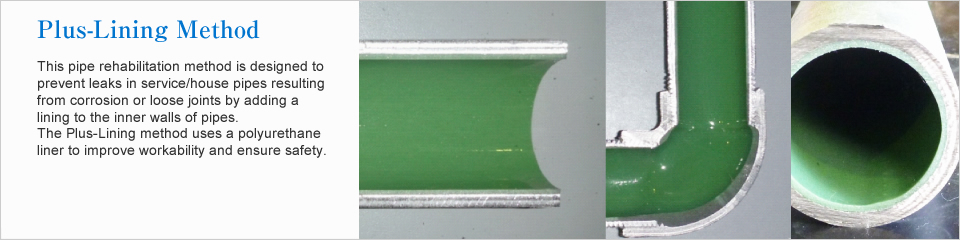

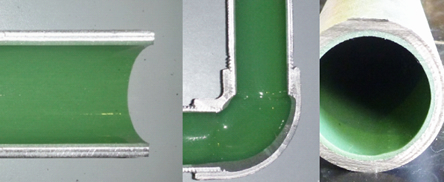

This method provides a lining to the inner walls of low-pressure service/house pipes (steel pipes with screw joints) to prevent leaks resulting from corrosion or loose joints. The Plus-Lining method uses a polyurethane liner.

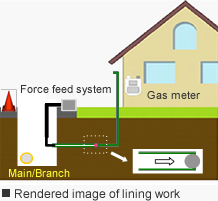

(1) Mix and stir the liner (resin and hardener).

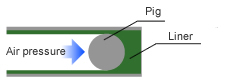

(2) Inject the liner into the pipe.

(3) Place the pig in the pipe. Connect a force feed system that feeds compressed air to form a lining.

- (1) Balance between shape retention and flexibility

The use of polyurethane ensures shape retention to resist the pressures of soil and water through corrosion pits and flexibility to minimize leaks in the event of gas pipe fracture. - (2) Reduced lining time and ensured lining quality

The liner viscosity is adjusted to be suitable for lining work.- ・Facilitates lining work and reduces the required time.

- ・After lining, the resin cures free of sagging to ensure lining quality.

- (3) Workability and safety considerations

The use of polyurethane is intended to reduce offensive odor and ensure the operator's safety.

| Applicable to | Scope of application |

|---|---|

| Pressure | Low pressure |

| Pipe type | Steel pipes with screw joints |

| Pipe size | 25A, 32A, 40A, 50A |

| Length | Up to 24 m (depends on piping conditions) |

| Item | Specifications |

|---|---|

| Resin type | Two-component cold setting polyurethane |

| Pot life | 70 min (depends on work environment) |

| Tensile strength | 17MPa |

| Elongation | 86% |