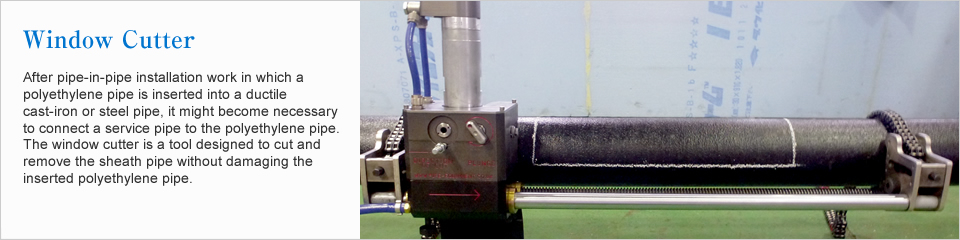

After pipe-in-pipe installation work in which a polyethylene pipe is inserted into a ductile cast-iron or steel pipe, it might become necessary to connect a service pipe to the polyethylene pipe. The window cutter is a tool designed to cut and remove the sheath pipe without damaging the inserted polyethylene pipe. This engineering method improves work safety and reduces work load.

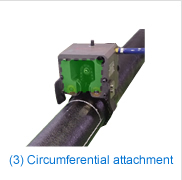

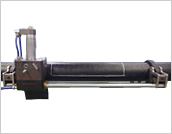

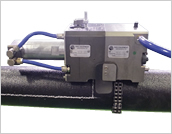

This system comprises (1) cutter, (2) axial attachment and (3) circumferential attachment and is driven by an air compressor. The same cutter cuts the pipe axially and circumferentially.

-

(1) Existing-pipe thickness measurement

* Ultrasonic measuring device -

(2) Cutting depth setting for installed cutter

-

(3) Axial cutting

-

(4) Circumferential cutting

-

(5) Work completed

Window opened and search device installed

| Materials | Cast-iron and steel pipes |

|---|---|

| Pipe size | 100mm in diameter min. |

| Pipe thickness | 20mm max. |

| Axial cutting length | 500mm per installation |

| Circumferential cutting length | 300° per installation |

- (1) The cutter has an anti-over cutting mechanism to cut and remove the sheath pipe, causing no damage to the inserted polyethylene pipe.

- (2) Opening a window in a 100mm diameter cast-iron pipe takes only some 30 minutes. To cut the entire circumference of the pipe takes as little as 40 minutes.

- (3) Use of an air compressor as a drive source and a cutter blade to cut the pipe minimizes sparks to ensure safe work.