This method, employed as an alternative to the pipe splitter method, uses a cable to replace gas pipes.

To promote the use of trenchless techniques, Toho Gas has employed the Pipe Splitter method to replace aging galvanized steel branch pipes. The Pipe Splitter method requires the operator to attach and remove screwed steel rods 80 cm in length and 5 kg in weight. With this method, reducing the work load and improving work efficiency have been desired. As a solution to this challenge, we have developed the Cable-and-Blade method, which uses a cable instead of rods to replace pipes.

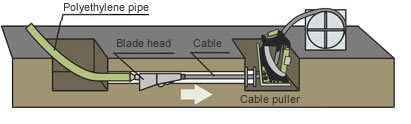

- (1) Feed the cable into an existing galvanized steel branch pipeline.

- (2) Attach a blade head to the end of the cable.

- (3) Pull the cable with a cable puller to draw a polyethylene pipe into the existing pipe while cutting the existing pipe and enlarging its diameter.

| (1) Reduced work load: | The use of a cable eliminates the need for transporting, attaching and removing rods. |

|---|---|

| (2) Reduced excavation area: | Compared with the rod method, the overall length of the equipment is shorter, this means that the pit length required is shorter, and the depth of the pit bottom from the existing pipe is smaller. |

| (3) Reduced work hours: | The cable is lighter than rods and eliminates the need for attaching and removing rods, thereby substantially reducing the time required for inserting a new pipe into the existing pipe. |

| (4) Extended applicability: | The cable system can be used on piping comprising some bends. |

| (5) Improved work efficiency and safety: |

Pulling the cable requires only two operators, with one operator operating the system and the other rewinding the cable. When pulling the cable, no operator is required in the pit. This ensures improved work safety. |

| Equipment | Specification |

|---|---|

| Hydraulic power unit |

Portable Output: 13 hp; Weight: 136 kg (Hydraulic power can be supplied from the excavator.) |

| Cable puller |

Max. pulling force: 27 tf Weight: 129 kg |

| Steel cable | diameter:19mm |

| Applicable to | Scope of application |

|---|---|

| Length | 20m to 50m per session |

| Pipe type | From steel pipe to polyethylene pipe |

| Pipe Size | 50A ・ 65A -> 75A |