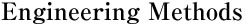

Both ends of the section to be replaced are excavated and cut. A pull-in device is placed in the destination pit. A rod with a blade expander and a PE pipe attached on one end is then inserted into the existing pipe. Subsequently, the PE pipe is pulled in and replaces the existing pipe while the blade expander breaks and expands the existing pipes.

| Application | Replacement of ductile cast-iron pipes and steel pipes with PE pipes |

|---|---|

| Pipes | Low-pressure ductile cast-iron pipes: 100A, 150A, 200A — Replacement with pipes of the same diameter Intermediate-pressure B ductile cast-iron pipes: 150A, 200A — Replacement with pipes of the same diameter Steel pipes: 200A — Replacement with pipes of the same diameter * Technology is under development for 100A and 150A steel pipes. |

| Length | Up to approximately 100 m |

| Pit | 5m x 1.2m x 40cm below pipe |

| Separation from other buried structures | Vertically: at least 30cm Horizontally: at least 30cm |

*This method's vibration and noise values have been confirmed to meet the vibration and noise standards set forth by the Aichi prefectural government.

- (1) Breaks ductile cast-iron pipes

The Stream method can easily break ductile cast-iron pipes with a maximum pulling force of 100 tf. - (2) Installation work without the need to enter the pit

The use of a rod handler and remote controller enables operators to carry out the operation safely

above ground by remotely attaching, decoupling, pushing, and pulling the rod. - (3)Installation causes minimum damage to PE pipes

Widening the existing installation and inserting the PE pipe at the ideal expansion rate minimizes

damage to the PE pipe during installation.

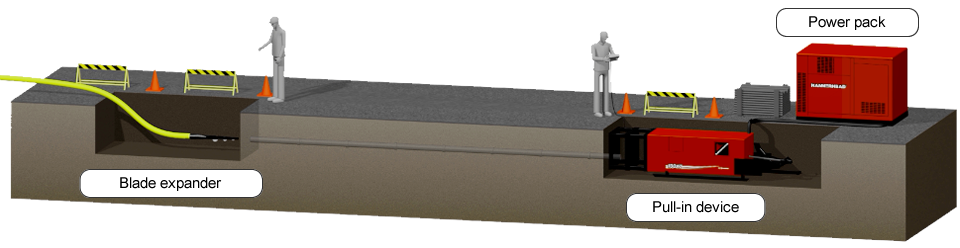

When setting the rod, the rod is first fitted to the cup at the tip of the rod carrier. The hydraulic cylinder then extends, causing the arm to descend and the rod to be loaded in the rod carrier. When removing the rod, the reverse sequence is followed for raising and withdrawing the rod.

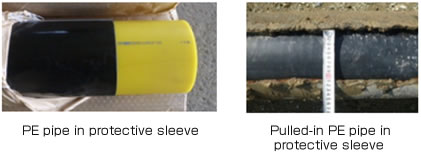

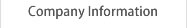

< PE pipe in protective sleeve >

PE pipe is encased in 1.5 mm thick sleeve to protect from scratches during installation.